Maximize your efficiency and quality

Innovative push systems for production freeze dryers

Product description

Our advanced pusher systems for production freeze dryers offer a variety of innovative features that significantly increase the efficiency and quality of your production processes.

Batch loading enables precise positioning of vials in the freeze dryer, which not only makes optimum use of the available space, but also significantly increases the overall efficiency of your processes.

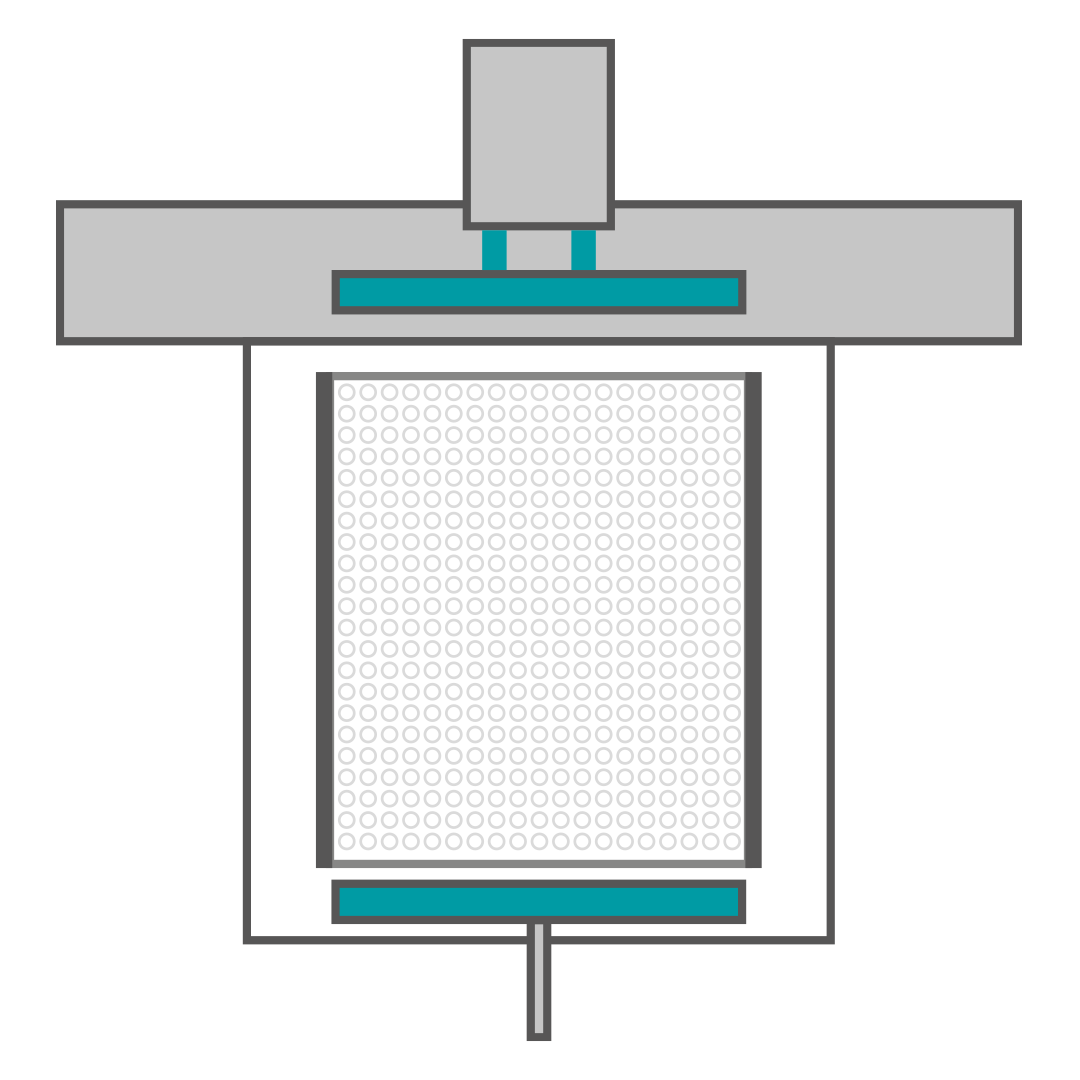

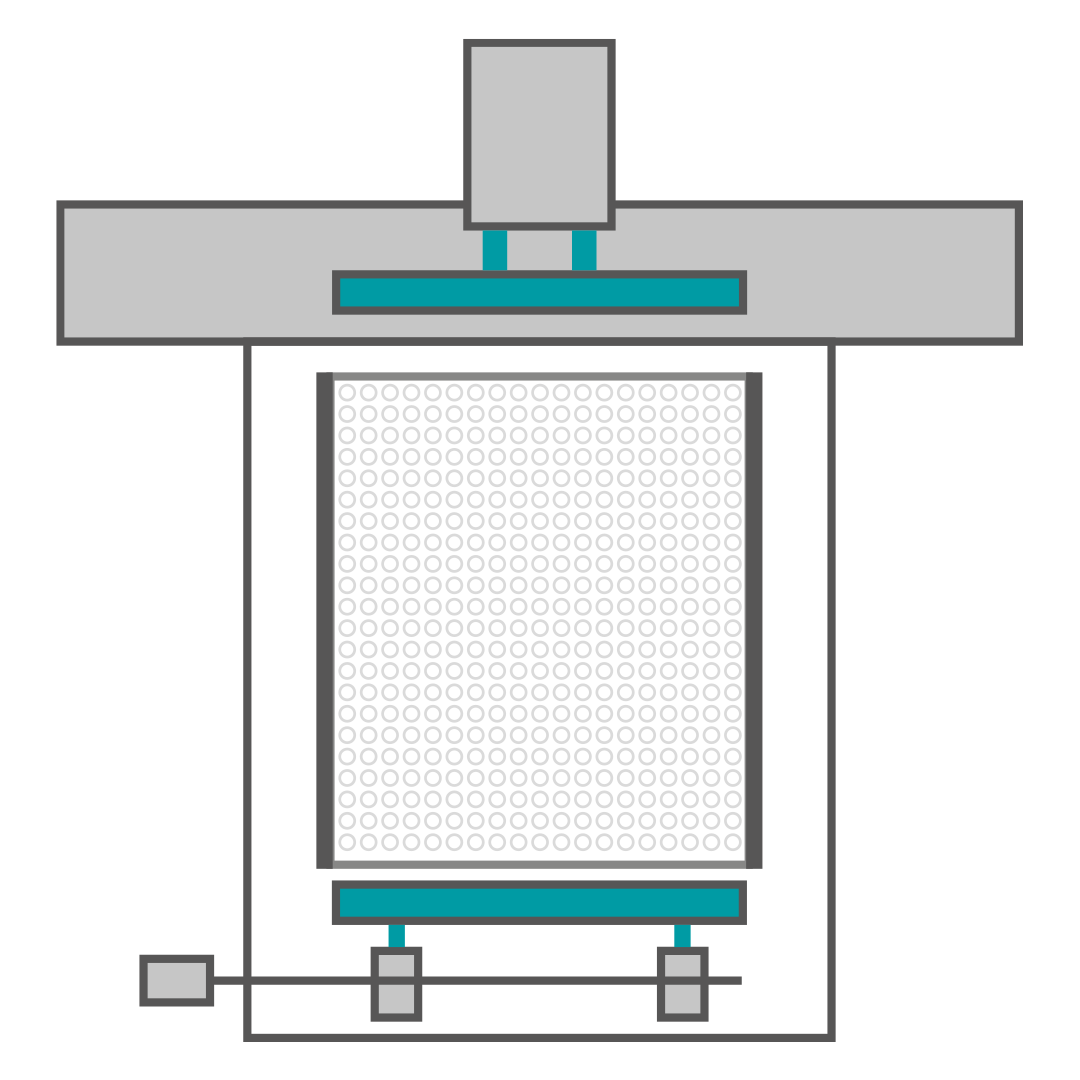

Push-InsidePush (PIP) System (LyoShuttle)

The loading principle is forming one structured row via conveyor and counting star. The vial row is pushed over via the shelf of the freeze dryer by the lyoshuttle robot.

For unloading the lyoshuttle robot travels underneath the shelf into the lyo, the shelf is lifted to the unloading level and the lyoshuttle robot pushes out a single or a multi row onto the conveyor.

Customized solutions

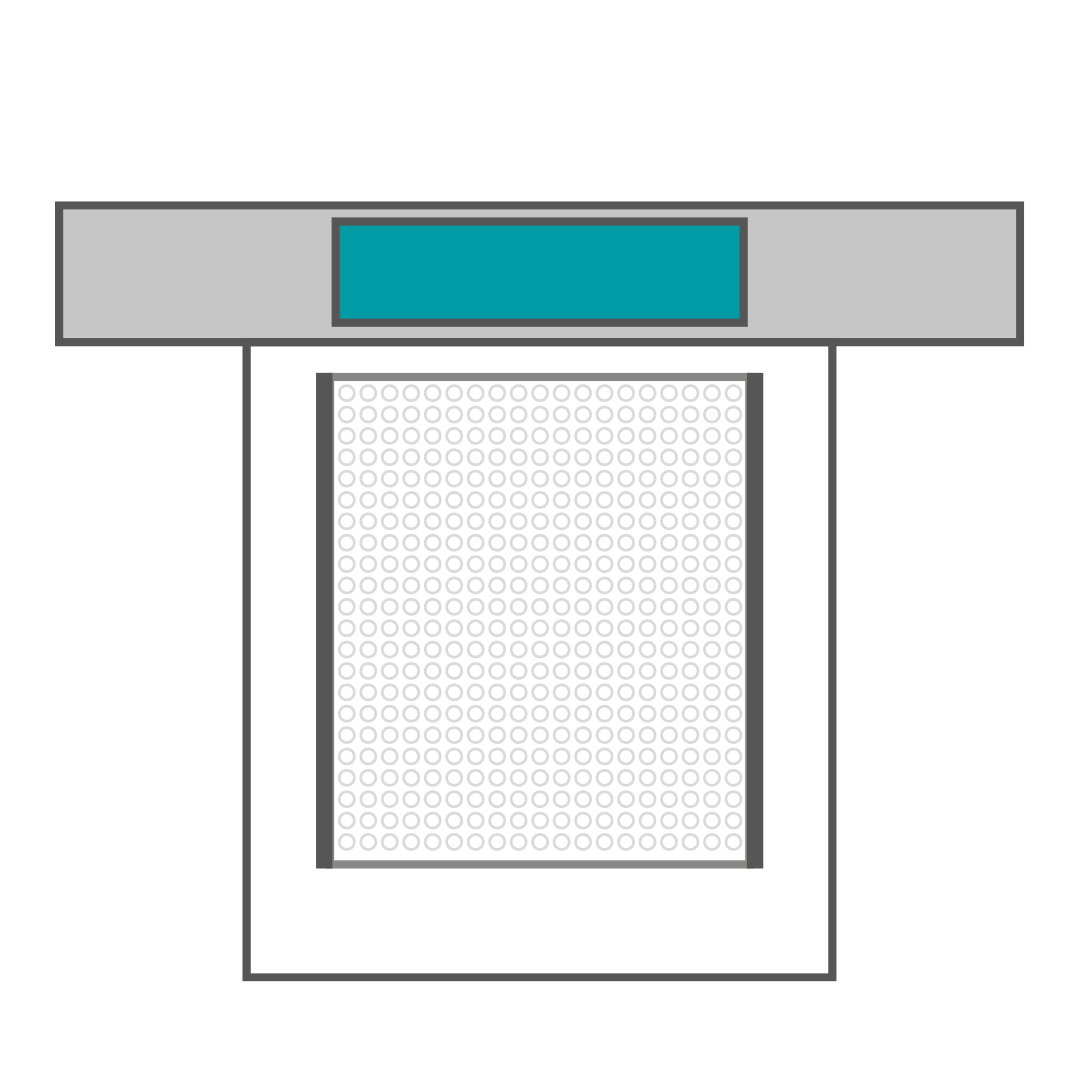

We offer various designs such as unloading pushers (PBP), chain pusher systems (PBC) and LyoShuttle (PIP), which are carefully selected and adapted to your production requirements.

Our overall concepts are based on a large number of standard assemblies that are perfectly tailored to your specific requirements.

Integration and high performance

The correct integration of loading and unloading systems ensures reliable buffering of the vials and enables a smooth production process. Our systems allow the simultaneous and fast unloading of several vial series, which makes a decisive contribution to increasing your production output. We offer flexible solutions for connection to a filling line, both after filling and to the capping machine.

Efficiency and safety

Our distribution systems can be used efficiently to precisely route vials to the appropriate freeze dryers when multiple freeze dryers need to be supplied.

Integration with containment solutions such as RABS or isolators ensures that products are handled safely in controlled environments. Format parts with antistatic properties minimize the risk of electrostatic unloading.

Highlight: LyoShuttle

Our fully automatic LyoShuttle loading and unloading system is specially designed for handling trays or vials. Using state-of-the-art technology, a battery-powered robot is moved along a rail to place the products safely and precisely on the shelves and transport them out again once the drying cycle is complete.

Learn more

Do you have any questions?